Why do we use direct drive actuators instead of cables?

When choosing a robotic arm, every detail matters.

One of the key differences between professional solutions (like RoboArm) and budget analogs is the drive system.

While cheap models often use cables (cable drives), we use high-precision electromechanical direct drive actuators.

Let's figure out why this is not just "more expensive", but a strategically important solution for tasks where accuracy and reliability are critical.

Problems with cable systems

Play and "elasticity":

The cables stretch and deform under load. This leads to positioning errors (up to 1-2 mm), which is unacceptable when working with microcircuits, decorating desserts or sorting fragile samples.

Wear and loss of calibration:

Over time, the cables wear out, stretch, require constant manual adjustment and replacement. This increases downtime and cost of ownership.

Vibrations and inertia:

The cables dampen the motor force unevenly. This causes microvibrations and a delay in response ("inertia"), interfering with smooth, human-like movements.

Surely you have seen videos with clumsy hands, where the fingers are squeezed in visible jerks: "tyrk-tyrk-tyrk". Modern electric motors do not have this, and with cables it is incurable.

Complexity of force transmission:

The more degrees of freedom the arm has, the more complex the cable system. This makes the arm bulky, less maneuverable, and more vulnerable to breakage.

The cables stretch and deform under load. This leads to positioning errors (up to 1-2 mm), which is unacceptable when working with microcircuits, decorating desserts or sorting fragile samples.

Wear and loss of calibration:

Over time, the cables wear out, stretch, require constant manual adjustment and replacement. This increases downtime and cost of ownership.

Vibrations and inertia:

The cables dampen the motor force unevenly. This causes microvibrations and a delay in response ("inertia"), interfering with smooth, human-like movements.

Surely you have seen videos with clumsy hands, where the fingers are squeezed in visible jerks: "tyrk-tyrk-tyrk". Modern electric motors do not have this, and with cables it is incurable.

Complexity of force transmission:

The more degrees of freedom the arm has, the more complex the cable system. This makes the arm bulky, less maneuverable, and more vulnerable to breakage.

Direct Drive Actuators Are the “Nervous System” of Our Robotic Arm

We believe that automation of delicate processes does not tolerate compromise.

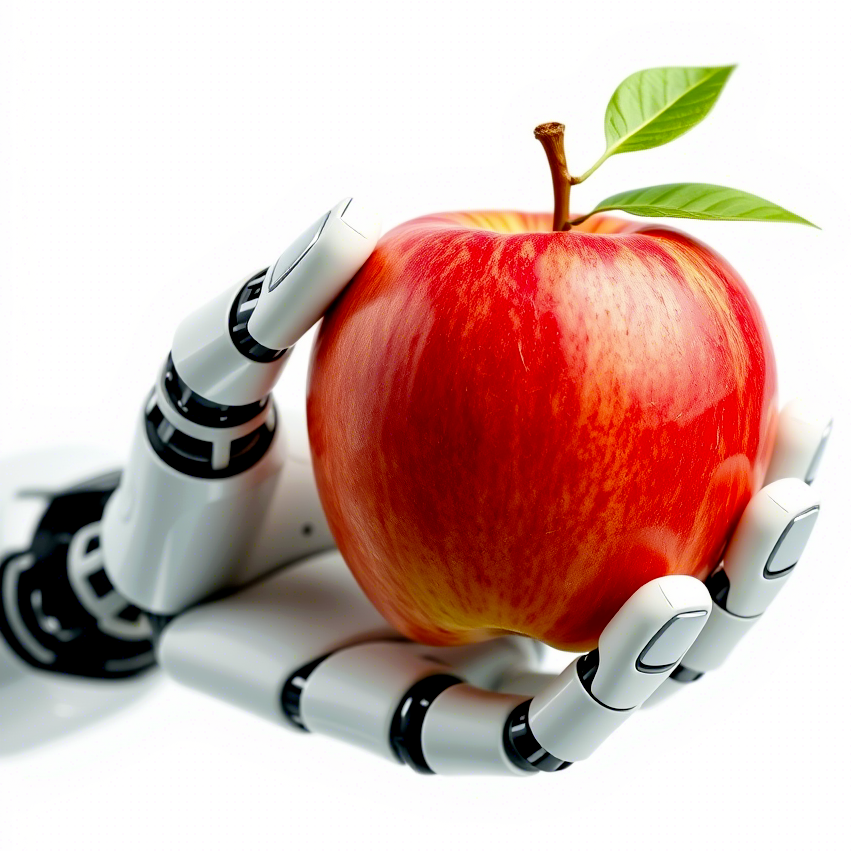

They provide the very same “human” dexterity, instant response to touch and unprecedented stability that make RoboArm an indispensable assistant in a restaurant kitchen, in a microchip lab or in the fist of a humanoid robot.

You pay not just for the “hardware” - you invest in a guarantee of precision, long service life and uncompromising quality of each operation.

This is the case when technology directly determines the result.

They provide the very same “human” dexterity, instant response to touch and unprecedented stability that make RoboArm an indispensable assistant in a restaurant kitchen, in a microchip lab or in the fist of a humanoid robot.

You pay not just for the “hardware” - you invest in a guarantee of precision, long service life and uncompromising quality of each operation.

This is the case when technology directly determines the result.

Advantages of Direct Drive Actuators

Reference precision:

The motor directly rotates the screw, which converts the movement. No intermediate links = no play, stretching or delays. This allows for the highest precision required for jewelry work, surgical manipulations or electronic assembly.

Rigidity and zero elasticity:

The actuator creates an absolutely rigid mechanical connection. Force, position and speed are controlled instantly and predictably. This is the basis for our pressure sensor system - the robot "feels" resistance as clearly as a human hand.

Durability and stability:

High-quality actuators (like ours) work tens of thousands of hours without losing accuracy. Calibration does not go wrong, maintenance is minimal. This reduces the total cost of ownership.

Smooth and fast:

The direct drive provides uniform acceleration and braking without jerking. This is critical for working with fragile objects (eggs, glass) or dynamic tasks (cooking at high speed).

Compact and powerful:

Actuators are integrated directly into the joints of the hand, making it lighter, more maneuverable and stronger with smaller dimensions. This allows for the creation of more “atomic” and functional replacement modules.

The motor directly rotates the screw, which converts the movement. No intermediate links = no play, stretching or delays. This allows for the highest precision required for jewelry work, surgical manipulations or electronic assembly.

Rigidity and zero elasticity:

The actuator creates an absolutely rigid mechanical connection. Force, position and speed are controlled instantly and predictably. This is the basis for our pressure sensor system - the robot "feels" resistance as clearly as a human hand.

Durability and stability:

High-quality actuators (like ours) work tens of thousands of hours without losing accuracy. Calibration does not go wrong, maintenance is minimal. This reduces the total cost of ownership.

Smooth and fast:

The direct drive provides uniform acceleration and braking without jerking. This is critical for working with fragile objects (eggs, glass) or dynamic tasks (cooking at high speed).

Compact and powerful:

Actuators are integrated directly into the joints of the hand, making it lighter, more maneuverable and stronger with smaller dimensions. This allows for the creation of more “atomic” and functional replacement modules.